Stay Smart with Smart Monitoring

by Roger Möller of Maillefer Extrusion O

Data gathering and data monitoring is a clear trend in the process industry—the way to truly know what is happening in the line in real time

with all the background data stored for future use. Smart Monitoring gives you many benefits and a leading edge with your end customers.

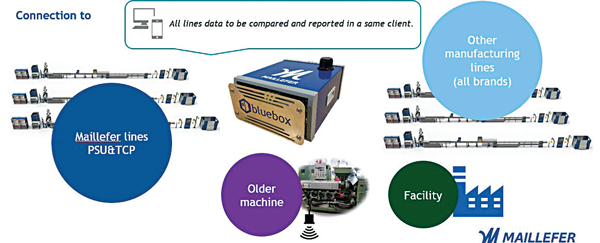

Maillefer offers a unique opportunity with this new smart product, where customers begin real-time monitoring of the performance of entire production lines or certain machines within a line. This monitoring can be the key process parameters from one line or from several lines producing the same quality, even lines from different suppliers. There is also a market need to monitor certain quality-related parameters. In this case, various measurement gauges are connected for real-time data collection, storage and analysis to secure end quality.

Within the Smart Monitoring family, Manufacturing Floor Data is the first of the two different product offerings. This product stores relevant data tags (i.e., data fields) from production for an unlimited time. You can assign tags to a Maillefer line, another supplier’s line or any machine or smart sensor. The goal is to make data available to analyze whenever needed. The storage is basically unlimited yet determined by disk capacity and a wise back-up strategy