High-Speed, On-Line Inspection & Measurement

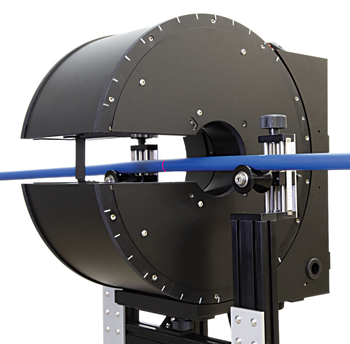

LaserLinc announces the launch of its high-speed, online inspection and measurement system, FlawSense. The system allows manufacturers of high-specifi cation tube, pipe and wire and cable to detect surface defects that may arise during the manufacturing process and to correct the process to eliminate these. The system tracks the defects so that these sections of product can be rejected thus ensuring end customers receive perfect, within specification product. FlawSense also provides highly accurate measurement of tube diameter and ovality, in fact significantly more accurately than laser micrometer systems and camera vision technology. FlawSense therefore provides a single instrument measurement solution for the manufacturer with the data visualized in TotalVu, LaserLinc’s well-renowned graphical user interface.