Polyurethane Resin Based FRP Rods Used in Optical Fiber Cables

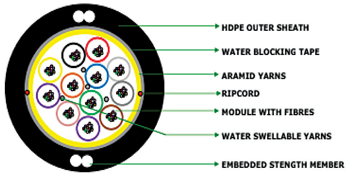

Fiber reinforced plastic rods are manufactured by impregnating the fiberglass with a resin matrix, such as polyester, epoxy or vinyl ester. The impregnated fibers are then pulled through a heated die (pultrusion process) to shape and cure the resin and create a rod with a consistent cross-section. Finally, the pultruded rods are cooled down to solidify the resin and maintain the desired shape. Depending on the application of these rods, some rods may undergo additional surface treatments or coatings to enhance specific properties such as adhesion. These FRP rods are used as strength members in optical fiber cables. They enhance the cable’s mechanical strength and durability and make the cable more resistant to bending, crushing and other physical stresses.