September 2024 Patents

USPTO Wire & Cable Industry Patents United States Patent and Trademark Office (USPTO) as compiled by the editors of WCTI.

Cable Feed Device, Cable Processing System and Method for Feeding a

Cable to a Cable Processing Machine

US Patent 12068568

Published August 20, 2024

Inventors: Bruno Weber, Ballwil, Switzerland; and Ivan Addario, Hochdorf,

Switzerland

Assignee: Komax Holding AG, Dierikon, Switzerland

A cable feed device for feeding a cable to a cable processing machine

includes a first rotatable roller and a second rotatable roller for guiding the

cable such that the cable can be arranged in a loop around the first roller

and the second roller, and a cable drive for transporting the cable. The first

roller is arranged stationary, wherein the second roller can be pushed or

pulled away from the first roller with a force, wherein the second roller has

a first state and a second state, wherein the second roller is locked in a first

position in the first state and is moved in the second state by the force such

that the distance between the first roller and the second roller changes

depending on the length of the cable between the two rollers.

Power Cable and Method for Manufacturing Power Cable

US Patent 12068088

Published August 20, 2024

Inventor: Tetsuya Mieda, Tokyo, Japan; Kazuyoshi Akizuki, Tokyo, Japan; and

Shingo Mitsugi, Tokyo, Japan

Assignee: Furukawa Electric Co., Ltd., Tokyo, Japan

www.uspto.gov

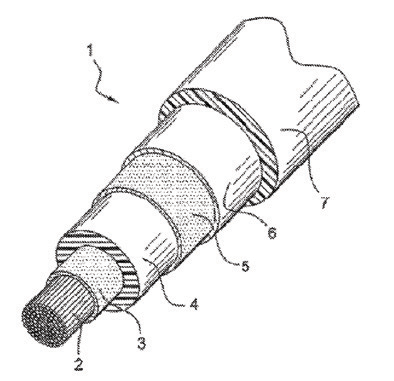

Provided is a power cable and a method for manufacturing a power cable

that reduces occurrence of uneven thickness of an insulating layer and voids

and peeling due to shrinkage and has good dielectric breakdown strength.

The power cable includes the insulating layer containing 15 mass% or more

of a propylene-based resin having a melting point of 110°C or higher with

respect to a whole. The power cable further includes a relationship between

a cooling rate X [°C/min] at the time of manufacturing an interface portion

in the insulating layer with the inner semiconductive layer and a cooling rate

Y [°C/min] at the time of manufacturing a central portion of the insulating

layer and is expressed by the relationship (Z), wherein X≥Yx0.8 . . . (Z).

Insulated Wire, Coil and Electrical or Electronic Equipment

US Patent 12068090

Published August 20, 2024

Inventors: Ayumi Yamamoto, Tokyo, Japan; Keisuke Ikeda, Tokyo, Japan; and

Keiichi Tomizawa, Tokyo, Japan

Assignee: Essex Furukawa Magnet Wire Japan Co., Ltd., Tokyo, Japan

An insulated wire, including: a conductor and an insulating film covering the

conductor; in which at least one insulating layer constituting the insulating

film contains: a thermosetting resin A, and a resin B that is ranked lower

than the thermosetting resin A in a tribo-electric series.

Off shore Submarine Cable for Off shore Wind Farm

US Patent 12068091

Published August 20, 2024

Inventor: Ross Wilson, Royal Wootton Bassett, Great Britain

Assignee: RWE Renewables GmbH, Essen, Germany

An off shore submarine cable for an off shore wind farm. The off shore

submarine cable has a power capacity between 3 MW and 2.5 GW, at least

one weighting element having a density of at least 5 g/cm3 at 20°C and at

least one armor package.

Welded Conductors for Power Transmission Cables

US Patent 12068086

Published August 20, 2024

Inventors: Audun Johanson, Oslo, Norway; and Jonas Larsson, Fredrikstad,

Norway

Assignee: Nexans, Courbevoie, France

An arrangement for welded conductors for power transmission cables

includes conductors welded by a high conductive welding material. A

method for production of such welded conductors and power transmission

cables including the welded conductors includes joining the conductor

elements by welding.

Connection Structure of Aluminum Cable and Terminal and Vehicle Including Same

US Patent 12068564

Published August 20, 2024

Inventor: Hai Xiao, Shenzhen, China; Jinlong Quan, Shenzhen, China;

Haidong Kang, Shenzhen, China; Jiye Huang, Shenzhen, China; and Ye Yuan,

Shenzhen, China

Assignee: BYD Company Limited, Shenzhen, China

A structure for connecting an aluminum cable and a terminal includes an

aluminum cable and a terminal. The aluminum cable includes a cable core.

The cable core is constructed with a cable welding portion. The terminal is

welded to the cable welding portion. A nominal cross-sectional area of the

cable core is M, and a welding area S between the cable welding portion and

the terminal meets 5M≤S≤6M.

Electric Cable with Improved Thermal Conductivity

US Patent 12062470

Published August 13, 2024

Inventors: Gabriele Perego, Milan, Italy; Christelle Mazel, Ruy, France; Dimitri

Charrier, Ecully, France; and Daphné Merle, Venissieux, France

Assignee: Nexans, Courbevoie, France

A cable is provided having at least one electrically insulating layer obtained

from a polymer composition with at least one polypropylene-based

thermoplastic polymer material and at least one inorganic filler selected

from aluminium oxide, a hydrated aluminium oxide, magnesium oxide, zinc

oxide and a mixture thereof; and a method for making the cable.

Partitioned Cable Joint for Superconducting Cables

US Patent 12062879

Published August 13, 2024

Inventors: Christopher Craighill, Cambridge, MA, USA; Alexey Radovinsky,

Cambridge, MA, USA; Rui Vieira, Billerica, MA, USA; Vincent Fry, Waltham,

MA, USA; Colin O’Shea, Cambridge, MA, USA; and Sera Evcimen, Brookline,

MA, USA

Assignee: Massachusetts Institute of Technology, Cambridge, MA, USA

Described is a partitioned cable joint comprising a plurality of physically

distributed joint elements with the plurality of joint elements taken together

defining a joint length. Joint elements may have a first mounting region

having a shape selected to accept one petal of superconducting cable and a

second mounting region having a shape selected to accept one petal of a

second conductor.

Cable Terminating Assembly with Electrically Insulating Cutting Blades

US Patent 12057685

Published August 6, 2024

Inventors: Martin Szelag, Bickenbach, Germany; Tobias Leininger,

Mannheim, Germany; Franz Mueller, Griesheim, Germany; and Ole Wiborg,

Mainz, Germany

Assignee: TE Connectivity Germany GmbH, Bensheim, Germany

A cable terminating assembly for terminating a cable having a wire includes

a wire manager having an end face facing in an insertion direction and a

connector housing with a reception opening receiving at least a part of the

wire manager. The end face holds the wire in a predetermined position

along the insertion direction. The connector housing has a cutting blade

formed by an electrically insulating material. The cutting blade cuts the wire

upon insertion of the wire manager into the connector housing.

Optical Fiber Cable Having Buffer Coupled to Armor Using Water-Block Adhesive and Method

US Patent 12050353

Published July 30, 2024

Inventors: Bradley Jerome Blazer, Granite Falls, NC, USA; Yangbin Chen, Lake

Elmo, MN, USA; Allen Michael Miller, Lenoir, NC, USA; Christopher Mark

Quinn, Hickory, NC, USA; and Randy Curtis Smith, Lincolnton, NC, USA

Assignee: Corning Research and Development Corporation, Corning, NY,

USA

Embodiments of the disclosure relate to an optical fiber cable. The optical

fiber cable includes a cable jacket having a first inner surface and a first

outer surface. The first inner surface defines a central bore along a

longitudinal axis of the optical fiber cable. The optical fiber cable also

includes optical fibers disposed within the central bore and a buffer tube

surrounding the optical fibers. The buffer tube has a second inner surface

and a second outer surface. The optical fiber cable also includes an armor

layer disposed between the first inner surface of the cable jacket and the

second outer surface of the buffer tube and a water-blocking adhesive

disposed between the armor layer and the first outer surface of the buffer

tube. The water-blocking adhesive extends along the longitudinal axis of the

optical fiber cable and around a circumference of the buffer tube.

Wire Drawing Monitoring System

US Patent 12048957

Published July 30, 2024

Inventors: Richard Sarver, Abingndon, MD, USA; Karl N. Naumann,

Abingdon, MD, USA; and Joao Norona, Abingdon, MD, USA

Assignee: Paramount Die Company, Inc., Abingdon, MD, USA

A drawing die system that has least two probes to measure various

characteristics of components of the die box or the wire being drawn

through the die box. The system includes a smart die that in which the

multiple probes send information to a data processing unit. The data

processing unit takes the information from the various probes and controls

the various parameters of the wire drawing process. One smart die has a

probe that collects information directly from a drawing die holder. The

smart die also includes a force sensor and is configured to allow a die box to

be displaced along an axis that is parallel to the direction in which the wire

is drawn. The data processing unit controls various wired drawing

parameters such as wire drawing speed, coolant pressure and the rate at

which the coolant is pumped through the system.

Superconducting Power Cable

US Patent 12051524

Published July 30, 2024

Inventors: Dag Willén, Klagshamn, Sweden; Carsten Thidemann, Jaegerspris,

Denmark; and Martin Pitzer, Bonn, Germany

Assignee: NKT Cables Group A/S, Brøndby, Denmark

A superconducting power cable having: a former including: an axially

stretchable core, and a plurality of elongated outer elements wound

helically around the core, wherein the core includes a first material and the

elongated outer elements include a second material thermally contracting

less than the first material at the operating temperature of the

superconducting power cable; and a superconducting conductor layer

arranged around the former.

Wires of Superelastic Nickel-Titanium Alloy and Methods of Forming the Same

US Patent 12043881

Published July 23, 2024

Inventor: Parikshith K. Kumar, Flagstaff , AZ, USA

Assignee: W. L. Gore & Associates, Inc., Newark, DE, USA

A nickel-titanium alloy with an average grain size of between 0.2 and 10

microns and a recoverable strain of greater than 9% is disclosed herein, in

which the alloy is formed using a method which involves applying a shape

set heat treatment to the nickel-titanium alloy. The heat treatment includes

applying heat at a temperature between 225°C and 350°C for a period of

time between 20 and 240 minutes.

Cable

US Patent 12047749

Published July 23, 2024

Inventors: Mark Schmidt, Breslau, ON, Canada; Aistis Januszko, Kitchener,

ON, Canada; Ming-Lun Dave Ma, Markham, ON, Canada; and Ilan Rashish,

Kitchener, ON, Canada

Assignee: Sonova AG, Staefa, Switzerland

A cable for a hearing device, comprising a plurality of conductors,

comprising conductors arranged in twisted pairs (TP1 to TP4) wound around

a plastically deformable core wire (FW).

Flame Retardant Electrical Cable

US Patent 12033772

Published July 9, 2024

Inventors: Vito Scrima, Milan, Italy; Luigi Caimi, Milan, Italy; Massimo Gola,

Milan, Italy; and Attilio Citterio, Milan, Italy

Assignee: Prysmian Spa, Milan, Italy; and Politecnico di Milano, Milan, Italy

Disclosed herein are flameretardant electric cables (10) having a core

containing an electric conductor (11) and an electrically insulating layer (12)

made from a flame-retardant polyolefin-based composition including a) a

cross-linked polyolefin as base polymer, b) silica, and c) carbon nanotubes,

wherein the amount of silica is from 5 to 10 wt% of the polyolefin-based

composition, and the amount of carbon nanotubes is from 0.5 to 2 wt% of

the polyolefin-based composition. Such cables have improved flame

retardant performances, especially regarding a lower occurrence of droplets

during burning, which render them capable of being certified in higher

classes of the current international standards, for example of the standard

EN 50399:2011/A1 (2016).

Cables for Cable Deployed Electric Submersible Pumps

US Patent 12033769

Published July 9, 2024

Inventors: Bradley Matlack, Shawnee, KS, USA; Varun Vinaykumar

Nyayadhish, Lawrence, KS, USA; Gregory Howard Manke, Overland Park, KS,

USA; Patrick Zhiyuan Ma, Lawrence, KS, USA; Jason Holzmueller, Lawrence,

KS, USA; Vincent Gerstner, Overland Park, KS, USA; William Goertzen,

Lawrence, KS, USA; Douglas Pipchuk, Calgary, AB, Canada; Joseph Varkey,

Richmond, TX, USA; Juan Amado, Houston, TX, USA; Willem Wijnberg,

Houston, TX,USA; Maria Grisanti, Missouri City, TX, USA; and Xiaohong Ren,

Sugar Land, TX, USA

Assignee: Schlumberger Technology Corporation, Sugar Land, TX, USA

Various cables for cable deployed electric submersible pumping systems

and methods of manufacturing such cables are provided. The cable includes

a power cable core and coiled tubing formed around the power cable core.

The power cable core includes one or more conductors, insulation

surrounding each conductor, and an elastomeric jacket extruded around

the insulated conductors. Various mechanisms, systems and methods are

described to anchor the power cable core in the coiled tubing and to

transfer weight from the power cable core to the coiled tubing.

High Voltage Submarine Cable Systems

US Patent 12030597

Published July 9, 2024

Inventors: Gerald Keith Sperling, Houston, TX, USA; and Masoud

Hajiaghajani, Houston, TX, USA

Assignee: Chevron USA Inc., San Ramon, CA, USA

A system for transmission of power off – shore comprises two or more

power stations operably connected with a high voltage cable system. The

high voltage cable system may comprise a dynamic, dry type high voltage

submarine cable of varying length configured to transmit at least about 45

megawatts of power. In some cases the dynamic, dry type high voltage

submarine cable comprises a first end connected to an off shore power

station and second end connected to a static submarine cable system which

is connected to an onshore power station. The systems may facilitate

transmission of power for applications such as compressing and/or

pumping subsea natural gas in deep water.

Wire with Platinum Composition for Contacting Temperature Sensors

US Patent 12024763

Published July 2, 2024

Inventor: Matthias Wegner, Hanau, Germany

Assignee: Heraeus Deutschland GmbH & Co. KG, Hanau, Germany

The invention relates to a wire for electrically contacting temperature

sensors, the wire consisting of at least 50 wt% of a platinum composition,

the platinum composition containing between 2 and 3.5 wt% tungsten, up to

47.95 wt% of at least one precious metal selected from the group consisting

of rhodium, gold, iridium and palladium and mixtures thereof, between 0.05

and 1 wt% oxides of at least one non-precious metal selected from the

group consisting of (i) zirconium, (ii) aluminum and (iii) zirconium and at

least one element selected from aluminum, yttrium and scandium, and, as

the remainder, at least 50 wt% platinum including impurities. The invention

also relates to a temperature sensor having such a wire, and to a method

for producing such a wire and such a temperature sensor.

Power Unit and Power Cable for Mobile Communication Base Station

US Patent 12027289

Published July 2, 2024

Inventor: Jong Seb Baeck, Anyang-si, South Korea

Assignee: LS Cable & System Ltd., Anyang-si, South Korea

The present disclosure relates to a power unit and a power cable for a

mobile communication base station, which have sufficiently low inductance

and thus minimize voltage oscillation regardless of a change of the amount

of power transmitted when communication load of a mobile

communication base station increases, thereby providing stable

communication services, and which enhance workability of connection to a

remote radio unit (RRU) at a base station.

Power Cable Health Monitoring Method

US Patent 12025568

Published July 2, 2024

Inventors: Alastair Bryan Godfrey, Fleet, Great Britain; and Chris D G Minto,

Hinckley, Great Britain

Assignee: Indeximate Ltd., Leicestershire, Great Britain

A power cable monitoring method which can be used to measure the

mechanical state of health of subsea power cables. This method uses the

magnetic properties of the load-bearing components of the power cable

and the current carried by the power cable to apply an alternating force to

itself. The only source of force from an alternating current in the cable

which is at the fundamental frequency (F0) of the electrical power originates

from magnetostriction of the steel armor. This force is predominantly axial.

The strength of the F0 signal is used as an indicator of strain in the cable,

where changes over time can be used to monitor the mechanical integrity of

the cable structure. 2F0 signals are complex sums of axial, radial and

tangential forces which are difficult to analyze. The 2F0 signal is therefore

predominantly used to normalize the F0 signal.