Patents for January 2025

Adhesive Tape for Wrapping Motor-Vehicle Cables

US Patent 12168744

Published December 17, 2024

Inventor: Timo Leermann, Wuppertal, Germany

Assignee: Certoplast Technische Klebebaender GmbH, Wuppertal, Germany

The subject matter of the invention is an adhesive tape, in particular a wrapping tape for sheathing cables (1) in automobiles, comprising a strip-type fabric backing (2, 3) that has at least one first layer (2) made of a woven fabric and a second layer (3) made of a nonwoven, the two layers being coupled together by a polymer layer (4) and/or by threads that penetrate both layers (2, 3), and comprising an adhesive layer (5) applied to at least one side of the backing (2, 3), characterised in that the nonwoven is produced from an aromatic polyamide.

Cable and Cable Manufacturing Method

US Patent 12170158

Published December 17, 2024

Inventors: Toyomitsu Asakura, Tokyo, Japan; Eiji Konda, Tokyo, Japan; and Yoshimitsu Kuroki, Tokyo, Japan

Assignee: Furukawa Electric Co., Ltd., Tokyo, Japan

A metallic cable includes, in order from an inner side thereof, a plurality of coated conduction wires, a press winding tape, a laminated tape and an outer jacket. The outer jacket is provided on an outer circumference of the laminated tape and such that it covers the outer circumference of the laminated tape. The outer jacket is made of polyethylene having a density greater than or equal to that of medium-density polyethylene (MDPE) (≥930 kg/m3), and more preferably made of high-density polyethylene (≥942 kg/m3). If polyethylene having a density that is equal to or greater than that of MDPE is used to form the outer jacket, the temperature that is appropriate for extruding MDPE approaches a bonding temperature range of the resin layer of the laminated tape. The resin layer and the metal layer can be bonded and joined together at an overlapped part, tightly enclosing a cable core.

Method for Forming Square-Wire Conductor

US Patent 12165782

Published December 10, 2024

Inventor: Wu Chen, Guangdong, China

Assignee: Hui Zhou Haiyun Electronics Co., Ltd., Guangdong, China

Disclosed is a method for forming a square-wire conductor, which includes: providing a circular conductor with a diameter d; passing the conductor through a gap of a longitudinal calendering roller to longitudinally calender the conductor up and down to form a conductor with flat upper and lower surfaces, the gap L1 of the longitudinal calendering roller is 0.886 d to 0.911 d; longitudinally and transversely straightening the conductor; passing the conductor through a gap of a transverse calendering roller to transversely calender the conductor left and right to form a conductor with flat left and right surfaces, the gap L2 of the transverse calendering roller is 0.886 d to 0.911 d; and longitudinally and transversely straightening the conductor.

High Resolution Headline Sonar Cable

US Patent 12164166

Published December 10, 2024

Inventor: Hjortur Erlendsson, Kopavogur, Iceland

Assignee: Hampidjan HF., Reykjavik, Iceland

Disclosed is a non-steel headline sonar cable having a strength member [5] and a core [1], the headline sonar cable comprising a length of a core-cable [10], the length of core-cable (10] comprising core [1] as well as comprising at least one fiber-optic conductor [2] that is: [i] disposed in a helical shape; and [ii] completely encased in a solid, flexible material. Also disclosed is a process for making a headline sonar cable. The headline sonar cable is capable of being wound on a winch under tensions and surging shocks experienced by a fishing trawler and provides high quality data signal transmission and resolution so as to permit use for transmitting data from high resolution sonars used to monitor fish caught in a fish trawl during operation.

Reduced Torque Wireline Cable

US Patent 12163394

Published December 10, 2024

Inventors: Joseph Varkey, Richmond, TX, USA; Mathew Varghese, Abu Dhabi, United Arab Emirates; Sheng Chang, Sugar Land, TX, USA; and Tam Tran, Sugar Land, TX, USA

Assignee: Schlumberger Technology Corporation, Sugar Land, TX, USA

A wireline cable includes an electrically conductive cable core for transmitting electrical power. The wireline cable further includes an inner layer of a plurality of first armor wires surrounding the cable core and an outer layer of a plurality of second armor wires surrounding the inner layer, wherein a diameter of the outer layer of the plurality of second armor wires is smaller than a diameter of the inner layer of the plurality of first armor wires.

Compatibilized Polymeric Compositions for Optical Fiber Cable Components

US Patent 12163014

Published December 10, 2024

Inventors: Karl M. Seven, Auburn, PA, USA; Mohamed Esseghir, Lawrenceville, NJ, USA; and Jeffrey M. Cogen, Flemington, NJ, USA

Assignee: Dow Global Technologies LLC, Midland, MI, USA

A polymeric composition includes (a) 1 wt % to 45 wt % of an ethylene-based polymer; (b) 50 wt % to 90 wt % of a polybutylene terephthalate having a melt flow index from 21 g/10 min. to 35 g/10 min at 250 C and 2.16 Kg; and (c) 3.5 wt % to 10 wt % of a compatibilizer comprising a maleated ethylene-based polymer and ethylene n-butylacrylate glycidyl methacrylate.

Signal Transmission Cable and Cable Assembly

US Patent 12159730

Published December 3, 2024

Inventors: Hiromitsu Kuroda, Tokyo, Japan; Tamotsu Sakurai, Tamotsu, Tokyo, Japan; Yoshiki Nakade, Hitachi, Japan; Detian Huang, Tokyo, Japan; and Xinweilong Li, Tokyo, Japan

Assignee: Proterial, Ltd., Tokyo, Japan

A signal transmission cable includes a conductor, an insulator covering a periphery of the conductor and a shield layer covering a periphery of the insulator. The shield layer includes a lateral winding shield portion composed of a plurality of metal wires being helically wrapped around the periphery of the insulator to cover the periphery of the insulator, and a batch plating portion composed of a hot dip plating, which is covering a periphery of the lateral winding shield portion. Where a diameter of the metal wire is d and a thickness of the batch plating portion from an outer surface of the metal wire is t, a formula t<0.5d is met over an entire cable circumference. When the signal transmission cable is bent in a U-shape within a range of a bending strain of 35% or less, no cracks occur in the batch plating portion.

Charging Cable

US Patent 12159735

Published December 3, 2024

Inventors: Naehyun Park, Seoul, South Korea; and Jiho Lee, Seoul, South Korea

Assignee: LG Electronics Inc., Seoul, South Korea

The present embodiment comprises an outer tube; and at least one charging line disposed inside the outer tube, in which an outer flow path through which cooling fluid passes is formed between the outer tube and the at least one charging line, the charging line comprises at least one charging conductor; and an insulating body surrounding the outer circumference of the at least one charging conductor, and in which an inner flow path through which cooling fluid passes is formed in the insulating body.

Cable Shielding

US Patent 12154704

Published November 26, 2024

Inventors: Arno Frahmann, Kleefeld, Germany; Maik Stratmann, Friesoythe, Germany; Hüseyin Turan, Garrel, Germany

Assignee:Bizlink Industry Germany GmbH, Roth, Germany

A cable shielding and an electrical conductor having such a cable shielding are provided. The cable shielding has a first wire winding and a second wire winding. The first wire winding has a plurality of turns. The first wire winding is wound in a first direction with a first pitch about a longitudinal axis. The second wire winding has a plurality of turns. The second wire winding is wound in a second direction, which is different from the first direction, with a second pitch about the longitudinal axis. Turns of the plurality of turns of the first wire winding and corresponding turns of the plurality of turns of the second wire winding cross one another in each case at a first crossing point in such a way that a plurality of first crossing points of the first wire winding and the second wire winding are present in the direction of the longitudinal axis. The plurality of first crossing points run at least approximately helically in the direction of the longitudinal axis.

Power Cable Assembly for a Power Distribution System Having an Integrated Cooling System

US Patent 12154706

Published November 26, 2024

Inventors: Grzegoprz Porebski, Podłże, Poland; Monika Pieszka-Lyson, Cracow, Poland; Dominik Kawalec, Brzoskwinia, Poland; and Pawel Kozak, Cracow, Poland

Assignee: Aptiv Technologies AG, Schaffhausen, Switzerland

A power cable assembly and a power distribution system incorporate an integrated cooling system. The power cable assembly includes a power cable core having an electrical conductor, an electrical conductor extending longitudinally, a plurality of longitudinally extending cooling pipes, and a thermal interface material (TIM) surrounding the cooling pipes and electrical conductor. The TIM is configured to thermally couple an external surface of the thermally conductive wall of each cooling pipe with an external surface of the insulating material of the electrical conductor such that the heat generated at the electrical conductor is transferred to the coolant medium circulating in the interior channel via the external surface of the cooling pipes over a heat transfer region.

Cable With Joints for the Connection of Cable Armour Non-Metallic Elements

US Patent 12148551

Published November 19, 2024

Inventors: Enrico Maria Consonni, Milan, Italy; and Federico Cordo′, Milan, Italy

Assignee: Prysmian S.p.A., Milan, Italy

The present disclosure relates to a cable comprising a cable core and an armor, the armor being formed by a plurality of consecutive sections of non-metallic tensile elements wound around the cable core, each section including a first non-metallic tensile element connected to a second non-metallic tensile element of the consecutive sections by a joint comprising a first socket and a second socket, each of said sockets comprising a flat body extending longitudinally along a longitudinal axis (S) between a proximal end and a distal end and comprising an inner through bore between a proximal aperture at the proximal end and a distal aperture at the distal end, the first and second non-metallic tensile elements having an end portion being housed in the inner through bore of respectively the first and second socket by the proximal aperture and secured therein by a bonding material, and each inner through bore being shaped to translationally and rotationally lock the bonding material; an interconnecting device translationally and rotationally locked in the distal apertures of the first and the second sockets and allowing the sockets to relatively rotate exclusively around at least one rotation axis (R) perpendicular to a plane where the socket body longitudinal axes (S) of the first and the second sockets lie.

Polymeric Compounds for Cable Coatings and Processes for Producing Same

US Patent 12142395

Published November 12, 2024

Inventors: Mohamed Esseghir, Lawrenceville, NJ, USA; and Anurima Singh, Manvel, TX, USA

Assignee: Dow Global Technologies LLC, Midland, MI, USA

Coated conductors having a conductor at least partially surrounded by a polymeric composition. The polymeric composition contains a broad-molecular-weight-distribution high-density ethylene-based polymer and a narrow-molecular-weight-distribution linear-low-density ethylene-based polymer, and has a density of at least 0.95 g/cm.sup.3. Also disclosed are processes for preparing the polymeric composition and for making the coated conductors. Further disclosed are articles of manufacture containing the same.

Cable Crimp Head

US Patent 12142887

Published November 12, 2024

Inventors: Qi Zhou, Shanghai, China; and Jinan Chen, Shanghai, China

Assignee: Ridge Tool Company, Elyria, OH, USA

The present disclosure relates to a crimper body and a crimper. The crimper body is applied to the crimper for crimping cables. The crimper body includes a body, which includes a fixed mold holder provided at one end of an upper portion of the body, and a protector. The protector is mounted to the body to reinforce and fix the fixed mold holder to rest of the body over the entire length of the fixed mold holder. The present disclosure further relates to the crimper including the crimper body. The crimper can effectively prevent fragments of the crimper body from dispersing when broken, and has the advantages of compact structure, light weight and low cost.

Device and Method for Twisting Single Cables

US Patent 12142391

Published November 12, 2024

Inventor: Michael Drab, Unteraegeri, Switzerland

Assignee: Komax Holding AG, Dierikon, Switzerland

A device and a method twist single cables about a twisting axis to form a cable bundle along an extension axis. The device includes single rotating units, which are spaced from one another at a variable distance, for separately holding cable ends at one end of the single cables, wherein each single rotating unit is mounted rotatably about an associated pivot axis, wherein each pivot axis runs substantially perpendicular to the extension axis of the cable bundle; a twisting unit for holding and twisting cable ends at the other end of the single cables; and a distance-adjusting apparatus for adjusting the variable distance.

Capacitive Cable for a Downhole Electro-Hydraulic Tool

US Patent 12139972

Published November 12, 2024

Inventors: Michaerl C. Romer, The Woodlands, TX, USA; Matthew P. Spiecker, Manvel, TX, USA; Peter A. Gordon, Yardley, PA, USA; and Dragan Stojkovic, Spring, TX

Assignee: ExxonMobil Technology and Engineering Company, Spring, TX, USA

A capacitive cable, as well as a method for operating a downhole electro-hydraulic (EH) tool using the capacitive cable, are described herein. The capacitive cable includes at least one standard conductor and at least one capacitive conductor including integrated wire-shaped capacitors. The method includes inserting a tool string including the capacitive cable and an attached downhole EH tool into a wellbore and conducting power from the surface to the downhole EH tool via the standard conductor(s) of the capacitive cable. The method also includes storing electrical energy downhole within the capacitive conductor(s) of the capacitive cable, and activating the downhole EH tool to provide for the rapid release of the electrical energy from the capacitive conductor(s) into the downhole EH tool, initiating an electro-hydraulic event within the wellbore.

Multi-Layer Fiber Optic Cable with a Cured Gelling Material and Methods of Making and Using Same

US Patent 12140473

Published November 12, 2024

Inventor: Michel LeBlanc, Houston, TX, USA

Assignee: Halliburton Energy Services, Inc., Houston, TX, USA

A fiber optic cable in the present disclosure comprises: an outer tube having an inner surface and an outer surface; a fiber in metal tube (FIMT) comprising one or more optical fibers, wherein the FIMT is disposed within the outer tube, and wherein the outer surface of the FIMT and the inner surface of the outer tube form an annular space; and a cured gelling material in the annular space. By incorporating the cured gelling material into the annular space, fluid migration through the annular space can be reduced, and sheer stress for strain coupling of the FIMT and the outer tube can be increased.

PoE Cable

US Patent 12136499

Published November 5, 2024

Inventors: Kyung Ho Ha, Daegu, South Korea; and Sang Sik Shin, Daegu, South Korea

Assignee: LS Cable & System Ltd., Anyang-si, South Korea

An Power over Ethernet (POE) which satisfies a Power-over-Ethernet plus (PoE+) power transmission characteristics and a data transmission rate of 1 Gigabits per second (Gbps) without an amplification device, such as an additional hub, at a distance of up to 200 meters, and to which an existing commercial connector is applicable.

Electrical Multi-Core Cable Crimp Ferrule, and Crimping Method

US Patent 12136777

Published November 5, 2024

Inventor: Dominik Klingler, Bensheim, Germany

Assignee: TE Connectivity Germany GmbH, Bensheim, Germany

A crimp ferrule includes an assembly portion assembled on a non-circular internal cross section of a multi-core cable and a diameter compensation portion forming a circular external cross section of the crimp ferrule on the multi-core cable. The assembly portion and the diameter compensation portion are arranged successively in an axial direction of the crimp ferrule.

Cable Reel

US Patent 12134541

Published November 5, 2024

Inventors: Fred Dowd, Princeton, MA, USA; Roger L. Cleveland, Jr., Arlington, TX, USA; and Jack David Hartman, McKinney, TX, USA

Assignee: Technology Container Corp., Desoto, TX, USA

A cable reel for retaining a continuous length of cable is preferably constructed using an inexpensive plastic material, such as corrugated plastic. In one embodiment, the cable reel includes a hollow tubular core with a set of outward radial tabs integrally formed at each of its ends. A single, disc-shaped, interior support flange is mounted within the interior of the core in circumferential contact therewith to provide structural rigidity. Additionally, on each end of the core, an annular inner flange and a disc-shaped outer flange are disposed in coaxial alignment with one another against opposing surfaces of its corresponding set of radial tabs and are fixedly secured together as part of the assembly process. The multi-flange construction enables the thickness, diameter and/or material properties of the ends of the cable reel to be adjusted, as needed, to accommodate the strength and dimensional requirements of the intended application.

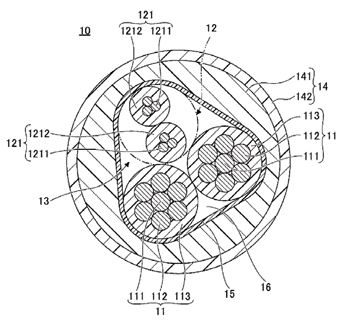

Multicore Cable

US Patent 12131847

Published October 29, 2024

Inventors: Takumi Ooshima, Tochigi, Japan; Masayuki Ishikawa, Tochigi, Japan; and Jo Yagisawa, Tochigi, Japan

Assignee: Sumitomo Electric Industries, Ltd., Osaka, Japan

A multicore cable includes power lines, and an outer jacket covering the power lines. The power lines include one first conductor disposed at a center, and second conductors disposed on an outer periphery of the first conductor, that are twisted together. Each of the first and second conductors includes 10 or more and 100 or less twisted second element wires. A direction of lay of the first element wires of the first conductor, a direction of lay of the second element wires of the second conductor, and a direction of lay of the first conductor and the second conductors of the power line are the same. A length of lay of the first element wires and a length of lay of the second element wires are greater than or equal to 8 mm and less than or equal to 22 mm.