Artificial Intelligence-Based Line Control and Predictive Maintenance Increases Productivity

The global demand for optical fiber cables is increasing at a growing rate. At the same time this market has seen very tight competition between the margins. The key to this problem is in increasing the efficiency of cable manufacturing lines. As an optical fiber cable consists of a bundle of buff er tubes, each potentially covering multiple optical fibers, it is evident that to produce one kilometer of optical fiber cable, multiple kilometers of loose buff er tube are required. Thus the need to improve loose tube production is obvious to enhance the overall efficiency gains. In addition to this, the buff er tube properties have high impact on the optical fiber cable performance.

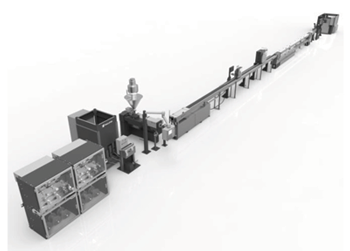

The efficiency of an optical cable manufacturing line can be mainly improved by increasing the line speed. In order to reach higher line speed, the manufacturing process itself must be highly robust and withstand abnormalities and changes in the manufacturing environment. In optical fiber cable manufacturing, more specifically the loose tube manufacturing process, this means that the excess fiber length and post-shrinkage must stay well under control during the whole production batch.