Numerical Simulation of Extrusion Process: A Powerful Tool to Save Time and Money

Numerical simulation of extrusion appears to be a good tool for diagnostics, expertise and found solutions. There are today many benefits to use extrusion simulation to achieve: (i) quick determination of causes and defects to reduce production downtime, (ii) optimization of designs before expensive prototyping and testing, (iii) exploration of new ways to improve operating conditions, product quality and production rate.

Here below are some examples from extrusion in cable production (based on Extrusion Simulation Software):

Impact of wear on screw performances then enter your own information and text.

Die drool phenomena: How to solve it by using extrusion simulation software.

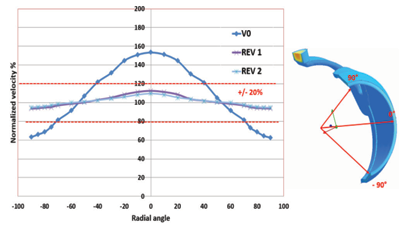

Process troubleshooting: Layer thickness distribution and welding line.