2023

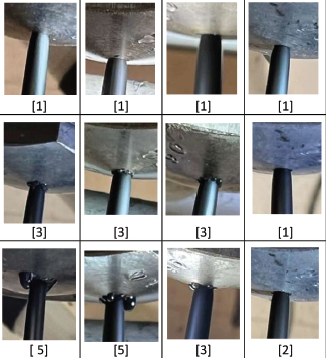

Efficient Cable Insulation & Impeccable Spark Test Results

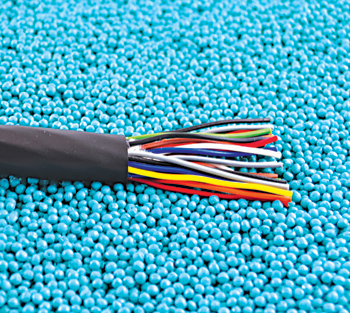

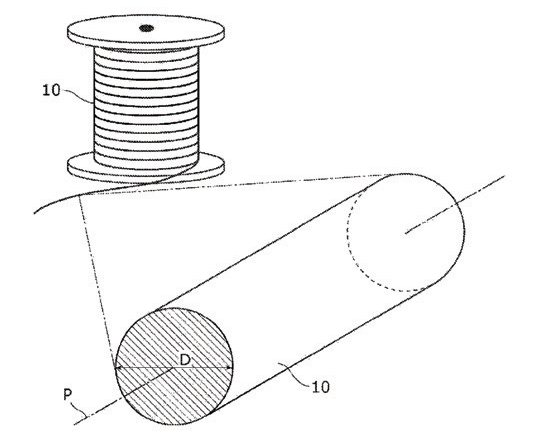

Color masterbatch producer reduces

granule size tenfold to improve dilution of the masterbatch in the cable compound

New Advancement in the Polyvinylidene Fluoride (PVDF) Materials

For many years, PVDF polymers have been used in high-performance cable applications including plenum communication cables, automotive cables, aviation and military cables and appliance wiring. The selection of PVDF polymers is largely due to a unique combination of properties, including flame and smoke resistance, abrasion resistance, high flexibility, chemical resistance, outdoor weathering resistance and the ability to be e-beam crosslinked. The wide range of useful properties provided by PVDF polymers helps make them a valuable tool for resolving unique problems under challenging applications. PVDF polymers available include both homopolymers and copolymers.

Read MoreStraight From the Show News & Images from wire Southeast Asia 2023

From September 20 to 22, 2023, BITEC in Bangkok, Thailand was abuzz with industry professionals, showcasing the vibrancy of the

Read MoreFluoropolymer Processing Aid Replacement in Cable Jacketing Compounds

Black polyethylene jacket compounds are widely used in the wire and cable industry for telecommunication and power cable applications. However, these filled polyethylene compounds are susceptible to die build-up during the extrusion process. Die build-up (DBU) refers to the unwanted accumulation of material on the open face of the extrusion die, which can lead to die streaking on the surface of the extruded product as well as additional time and cost to shut down the line and clean the tooling. Excessive die build-up negatively impacts the aesthetic quality and properties of the final product, posing a challenge for the wire and cable as well as the plastic industry.

Read MoreRange of Metal Deactivators for Wire & Cable Applications

Auto-oxidation reactions in plastics are initiated and accelerated not only by heat, light and mechanical stress, but also by contact with metals. Applications that come into contact with metal include polyolefin insulations for wire coatings, automobile parts and pipes as well as, elastomeric compounds for coatings and insulation. Metal deactivators are used as polymer additives to control the metal-catalyzed oxidation of these hydrocarbon materials, thereby improving the stability of these polymers, including their long-term stability in these applications.

Read MoreComposite Conductor Cores Connecting the Future

ccording to Bill Gates, over 1000 gigawatts of clean energy projects—approximately the current size of the entire USA power grid—are awaiting approval. Despite huge potential, infrastructure work on this scale is a huge undertaking so intelligent engineering and efficient design will be essential for return on investment for utilities providers. This article explains how composite conductor cores can extend maintenance intervals, reduce infrastructure costs and improve performance for power line installations

Read MoreEquipment Revolutionizes Solar Cable Package for Sustainable Energy Sector

by Olga Berlinberg, WINDAK OÜ Global demand for high-quality solar cables has surged with the shift towards renewable energy sources

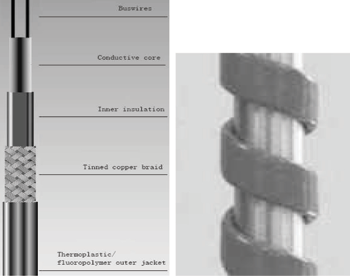

Read MoreAerospace Wire and Cable Applications

Aerospace wire and cable applications are essential for transmitting power, data and signals throughout various aircraft and spacecraft systems. These components are subject to rigorous standards and requirements due to the extreme conditions and safety considerations in aerospace engineering.

The AS9100:2016 quality management system (QMS) is a necessary certification when manufacturing aerospace harnesses and assemblies. It is a revision of the previous version, AS9100:2009, based on the international QMS standard ISO 9001.

Read MoreClarifying the Changes: Update on Revisions to UL Certification Documents,

A review of upcoming standards proposals and recently published revisions is important, so that both manufacturers and users are aware of the changes, understand the ramifications of the changes and may take the appropriate steps to ensure that the wire and cable manufactured to these standards continue to comply with the requirements.

Read MoreMeasurement of 10 GΩ Isolation at 100V: New External Measurement Device Option

Margaret Bishop, Technical Marketing at CAMI Research Inc., Acton, MA, USA, the manufacturer of the CableEye® automation-ready cable and harness

Read MoreCabling for Fault-Managed Power Systems (What is Class 4?)

by Ronald Tellas, Belden Remote powering enables the ability to easily place end devices where they are needed instead of

Read MorePatents for November/December 2023

USPTO Wire & Cable Industry Patents as compile by the editors of WCTI for November 2023. Methods For Bonding Stranded

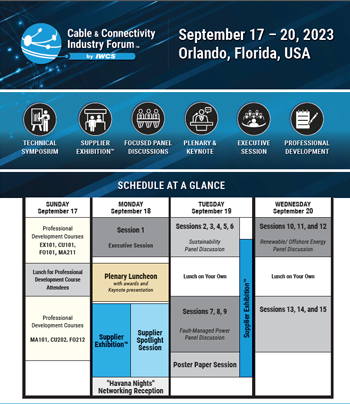

Read MoreIWCS Cable & Connectivity Industry Forum Preview

Please take time to review this Event Preview to see the many important topical issues and technologies that will be discussed with

Read MoreExpo WireTech Preview

Expo WireTech takes place October 4 and 5, 2023, at the Expo Convention Center, which is located in Chihuahua, Mexico.

Read MoreHow Politics in Mexico Are Affecting Manufacturers Everywhere

by John Paul McDaris, Entrada Group It was just over five years ago that companies were enticed by the business-friendly

Read MoreCase Study: Game-Changing Resultswith New Cut and Strip Machines

Buckeye Electrical, located in Botkins, OH, USA, is a family owned and operated manufacturer of custom wire harness and cable

Read MoreAutomated Wire Marking System

Ideal for applying self-laminating and flag labels to wires, cables and harnesses, the durable VortexID from IDENTCO, Ingleside, IL, USA,can

Read More