USPTO Wire & Cable Industry Patents for March 2021

Terminal-Attached Electric Wire and Wire Harness

United States Patent 10,931,038 – Issued: February 23, 2021

Inventors: Hiroyuki Hasui, Yokkaichi, Japan; Yoshiaki Yamano, Yokkaichi, Japan; Hiroshi Sudou,

Yokkaichi, Japan; Takayasu Sugihara, Osaka, Japan; and Misaton Ueki, Osaka, Japan

Assignee: AutoNetworks Technologies, Ltd., Yokkaichi, Japan; Sumitomo Wiring Systems, Ltd.,

Yokkaichi, Japan; and Sumitomo Electric Industries, Ltd., Osaka, Japan

Provided is a terminalattached electric wire including: an electric wire having a conductor made of

aluminum or an aluminum alloy whose outer circumference is covered with an insulating layer; and

a terminal member made of copper or a copper alloy and attached to a conductor-exposed portion

exposed from the insulating layer at an end portion of the electric wire. The terminal member

includes a coating layer made of an electrically conductive material and formed at a terminal exposed portion except for a place of contact with the conductor in a surface of the terminal member, and an oxide film of the electrically conductive material formed in a surface of the coating

layer. The electrically conductive material is a metal or an alloy which forms an oxide film having a

thickness of more than or equal to 20 nm in a surface thereof.

Coaxial Cable and Medical Cable

United States Patent 10,930,416 – Issued February 23, 2021

Inventors: Takanobu Watanabe, Hitachi, Japan; Detian Huang, Hitachi, Japan; Kimika Kudo,

Kitaibaraki, Japan; and Haruyuki Watanabe, Hitachi, Japan

Assignee: Hitachi Metals, Ltd., Tokyo, Japan

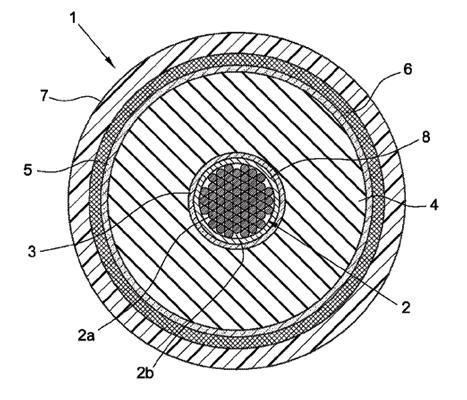

A coaxial cable includes a central conductor, a plurality of insulating twisted threads or insulation

strings wound therearound, each insulating twisted thread including a plurality of insulating strings

twisted together, a cover layer provided around the insulating twisted threads or the insulation

strings to form a gap to the insulating twisted threads or the insulation strings, and an outer

conductor and a jacket provided on the outer periphery of the cover layer.

Data Cable for Areas at Risk of Explosion

United States Patent 10,930,415 – Issued February 23, 2021

Inventors: Uwe Rudolf, Ahrensfelde, Germany; Maik Stratmann, Friesoythe, Germany; and Benedikt

Engler, Oldenburg, Germany

Assignee: Leoni Kabel GmbH, Roth, Germany

The invention relates to a data cable. One embodiment of the data cable has at least one pair of

wires and a cable sheath surrounding the at least one pair of wires. The at least one pair of wires

has two wires twisted together in the longitudinal direction of the data cable. Cavities between the

at least one pair of wires and the cable sheath are at least partially filled with a filler. The filler has a

viscosity which is such that it adheres in the data cable in such a way as to remain in the data cable

at least nearly completely when there is a specified pressure difference between one end of the

data cable and the other end of the data cable.

Method for Extracting Crosslinking By-Products from a Crosslinked Electrically Insulating System of

a Power Cable and Related Power Cable

United States Patent 10,930,414 -Issued February 23, 2021

Inventors: Rodolfo Sica, Milan, Italy; and Alessandro Rolla, Milan, Italy

Assignee: Prysmian SpA, Milan, Italy

An energy cable comprises at least one cable core comprising an electric conductor, a crosslinked

electrically insulating layer, and particles of a zeolite system comprising at least a first zeolite and a

second zeolite placed in the cable core. A method for extracting crosslinking by-products from a

cross-linked electrically insulating layer of an energy cable core comprises manufacturing the

energy cable core comprising particles of the above said zeolite system, heating the energy cable

core up to a temperature causing migration of the crosslinking by-products from the crosslinked

electrically insulating layer, and placing a metal screen around the energy cable core.

Cored Wire with Particulate Material

United States Patent 10,927,425 – Issued February 23, 2021

Inventor: David L. Campana, Sr., Lorain, OH, USA

A cored wire for refining molten metal includes a reactive core material that is in the form of a solid

rod. A non-reactive particulate material radially surrounds the solid core material, and an exterior

metal jacket radially surrounds the particulate material. The particulate material may include wood

or other material that when introduced into the molten metal, undergoes thermal decomposition to

release carbon dioxide, hydrocarbons, or combinations thereof as a shroud around the core

material.

Wire for an Ignition Coil Assembly, Ignition Coil Assembly, and Methods of Manufacturing the Wire

and Ignition Coil Assembly

United States Patent 10 923 887 – Issued February 16, 2021

Inventors: Massimo Augusto Dal Re, Concordia Sulla Secchia, Italy; Giovanni Betti Beneventi,

Modena, Italy; and Stefano Papi, Modena, Italy

Assignee: Tenneco Inc., Lake Forest, IL, USA

A wire for an ignition coil assembly and/or a corona ignition assembly is provided. The wire

comprises a wire core including a copper-based material, and a coating applied to the wire core.

The coating includes at least one of a carbon-based material and magnetic nanoparticles. The

carbon-based material can include graphene and/or carbon nanotubes, and the magnetic

nanoparticles can include graphene and iron oxide (Fe.sub.3O.sub.4). Typically, the coating includes

a plurality of layers. For example, the coating can include a layer of the graphene and/or carbon

nanotubes, and/or a layer of the magnetic nanoparticles. The coating can also include a layer of

insulating material, such as enamel. According to another embodiment, the coating includes iron,

nickel, and/or cobalt plated onto the wire core.

Flame Retardant Electrical Cable

United States Patent 10,923,246 – Issued February 16, 2021

Inventors: Franco Galletti, Casatenovo, Italy; Elena Roda, Segrate, Italy; and Giuseppe Merigo, Milan,

Italy

Assignees: Prysmian SpA, Milan, Italy, and Politecnico di Milano, Milan, Italy

A flame-retardant electric cable has a core including an electric conductor and an electrically

insulating layer. The electrically insulating layer includes a flame-retardant polyolefinbased

composition which includes, as base polymer, a mixture of at least two polyolefin homopolymers

and/or copolymer wherein at least one is a low-density polyethylene copolymer having a density

lower than 0.915 g/cm3. The flame-retardant polyolefin-based composition also includes calcinated

kaolin in an amount greater than 3 phr, a metal hydroxide in an amount greater than 10 phr, and

an alkyl or alkenyl alkoxy siloxane. The alkyl or alkenyl alkoxy siloxane is in an amount ratio of from

1:25 to 1:50 with respect to the sum of the amounts of calcinated kaolin and of the metal hydroxide.

Aluminum Alloy Wire Rod and Producing Method Thereof

United States Patent 10,920,306 – Issued February 16, 2021

Inventors: Toru Sumi, Tokyo, Japan; Kazuya Nishi, Tokyo, Japan; Shohei Hata, Tokyo, Japan; Takashi

Hayasaka, Tokyo, Japan; and Takeshi Usami, Tokyo, Japan

Assignee: Hitachi Metals, Ltd., Tokyo, Japan

An aluminum alloy wire rod has a chemical composition consisting of 0.1 to 1.0 mass % of Co, 0.2 to

0 5 mass % of Zr 0 02 to 0 09 mass % of Fe 0 02 to 0 09 mass % of Si 0 to 0 2 mass % of Mg 0 to

3/15/2021 Wire and Cable Technology International March/April 2021

https://www.bluetoad.com/publication/?m=6619&i=699698&p=58&pre=1 4/9

0.5 mass % of Zr, 0.02 to 0.09 mass % of Fe, 0.02 to 0.09 mass % of Si, 0 to 0.2 mass % of Mg, 0 to

0.10 mass % of Ti, 0 to 0.03 mass % of B, 0 to 1.00 mass % of Cu, 0 to 0.50 mass % of Ag, 0 to 0.50

mass % of Au, 0 to 1.00 mass % of Mn, 0 to 1.00 mass % of Cr, 0 to 0.50 mass % of Hf, 0 to 0.50 mass

% of V, 0 to 0.50 mass % of Sc, 0 to 0.50 mass % of Ni, the balance being Al and inevitable impurities,

and a metal structure including Al crystal grains, an Al–Co–Fe compound and an Al–Zr compound.

The Al crystal grains having a crystal grain diameter of 10 .mu.m or less have an area ratio of 90% or

more. The wire rod has a tensile strength of 150 MPa or more, an electrical conductivity of 55% IACS

or more and when heated at 200 deg C. for 10 years, a strength of 90% or more of its initial state

strength.

Method for Manufacturing an Electrical Wire

United States Patent 10,916,360 – Issued February 9, 2021

Inventors: Yuto Ito, Utsunomiya, Japan; Yoshio Shionome, Utsunomiya, Japan; Takashi Oguri,

Utsunomiya, Japan; and Jin Omori, Utsunomiya, Japan

Assignee: Yazaki Corporation, Tokyo, Japan

There is provided a method for manufacturing an electrical wire. The electrical wire includes a rodlike conductor having a shape corresponding to a predetermined wiring route and also having

rigidity to enable the rod-like conductor to maintain the shape, and an insulation sheath covering

the rod-like conductor. The method includes: preparing a plurality of rod-like preliminary

conductors having the rigidity so as to correspond to a plurality of sub routes into which the wiring

route is divided; processing at least one of the plurality of preliminary conductors into a shape

conforming to the corresponding sub routes; connecting the plurality of preliminary conductors

together to form the rod-like conductor; and forming the insulation sheath to cover the rod-like

conductor.

Wire Harness

United States Patent 10,913,405 – Issued February 9, 2021

Inventor: Hikaru Omae, Yokkaichi, Japan

Assignee: Sumitomo Wiring Systems, Ltd., Mie, Japan

A wire harness that includes a wire having a first wire, a second wire that is more bendable than the

first wire, and a connection for electrically connecting the first wire and the second wire to each

other; a tube for accommodating at least one of the first wire and the second wire; and a covering

ventilation that is tubular, has a covering for surrounding the connection and a surrounding region

of the connection of the wire, and is connected to the tube.

Optical Communication Cable

United States Patent 10 914 907 – Issued February 9, 2021

Inventors: Michael Emmerich, Berlin, DE, USA; Warren Welborn McAlpine, Hickory, NC, USA; and

Guenter Wuensch, Neustadt, DE, USA

Assignee: Corning Optical Communications LLC, Charlotte, NC, USA

An optical communication cable is provided having a cable body with an inner surface defining a

passage within the cable body and a plurality of core elements within the passage. A film surrounds

the plurality of core elements, wherein the film directs a radial force inward onto the plurality of

core elements to restrain and hold the plurality of core elements in place.

Cable Reel

United States Patent 10,913,632 – Issued February 9, 2021

Inventors: Rakesh Thakare, Cary, NC, USA; Caichun Song, Changzhou, China; Phillip S. Bowen,

Chatham, VA, USA; Marvin Bryant, Chatham, VA, USA; Paul R. Boucher, Callands, VA, USA); and Barry

Holt, Ottawa, Canada

Assignee: Amphenol Corporation, Wallingford, CT, USA

A cable payout apparatus that comprises a bag with a payout opening for dispensing cable, and first

and second frames inside the bag. A first flange is configured to be rotatably coupled to the first

frame. A second flange is configured to be rotatably coupled to the second frame. An elongated

wall extends from the first flange and releasably couples to the second flange for supporting a coil

of cable between the first and second flanges. The first frame is positioned in the base of the bag

and the second frame is positioned at the cover of the bag, such that when the cover of the bag is

closed with respect to the base of the bag, the second frame releasably couples with the second

flange and such that when the cover of the bag is opened, the second frame decouples from the

second flange.

Rodent Repellent Fiber Optic Cable

United States Patent 10,910,128 – Issued February 2, 2021

Inventors: Clyde Stephan Munsell, Chula Vista, CA, USA; James Dalgleish Reid, San Diego, CA, USA;

and Richard William Hanawalt, Ventura, CA, USA

Assignee: STICK-IN-THE-MUD, LLC, Chula Vista, CA, USA

A rodent repellent fiber optic cable includes an outer jacket, one or more optical fibers, and a

repellent electrostatically bonded to at least one component of the cable. The one or more optical

fibers extend longitudinally through an interior of the cable. The repellent is preferably an olfactory

stimulant, such as menthol, configured to repel rodents. In various embodiments, the cable also

includes one or more separators and/ or a sheath In embodiments that employ separators at least

3/15/2021 Wire and Cable Technology International March/April 2021

https://www.bluetoad.com/publication/?m=6619&i=699698&p=58&pre=1 6/9

includes one or more separators and/ or a sheath. In embodiments that employ separators, at least

one optical fiber is wrapped in, or otherwise surrounded by a separator. In embodiments that

employ a sheath, the sheath surrounds an assembly of the cable’s internal components.

Method for Rolling Metal Wire or Rod with Assistance of Combined Static Magnetic Field

United States Patent 10,906,076 – Issued February 2, 2021

Inventors: Hongming Wang, Zhenjiang, China; and Guirong Li, Zhenjiang, China

Assignee: Jiangsu University, Zhenjiang, China

The present invention relates to the technical field of extruding, rolling and drawing metal wire or

rod with assistance of a combined static magnetic field, characterized by providing, in a moving

direction of a metal wire or rod, a gradient static magnetic field generated by a combination of a

permanent magnet and a steady electromagnet; and after a raw material for rolling the metal wire

or rod is processed by the gradient static magnetic field, performing rolling extrusion and pulling on

the material. For multiple passes of rolling extrusion and pulling, the static magnetic field

processing is performed before each pass of rolling.

Twisted Wire Conductor for Insulated Electrical Wire, Insulated Electrical Wire, Cord and Cable

United States Patent 10,902,966 – Issued January 26, 2021

Inventor: Hiroshi Kaneko, Tokyo, Japan

Assignee: Furukawa Electric Co., Ltd., Tokyo, Japan

This twisted wire conductor 10 for an insulated electrical wire is configured so as to be in a mixed

state in which a first conductor 20 and a second conductor 40 are twisted together. The first

conductor comprises a specific aluminum alloy: which has an alloy composition that contains, by

mass %, 0.2-1.8% of Mg, 0.2-2.0% of Si, 0.01-0.33% of Fe and a total of 0.00-2.00% of one or more

elements selected from the group consisting of Cu, Ag, Zn, Ni, Co, Au, Mn, Cr, V, Zr, Ti and Sn, with

the remainder comprising Al and unavoidable impurities; which has a fibrous metal structure in

which crystal grains extend in one direction; and in which the average value of a dimension t which

is perpendicular to the longitudinal direction of crystal grains is 400 nm or less in a cross section

parallel to this one direction. The second conductor has a higher electrical conductivity than the first

conductor 20 and comprises a metal or alloy selected from the group consisting of copper, copper

alloys, aluminum and aluminum alloys. The twisted wire conductor exhibits high electrical

conductivity, high strength and excellent bending fatigue resistance, and enables a reduction in

weight.

Nanowire and Micro Wire Fabrication Technique and Product

United States Patent 10 900 137 – Issued January 26, 2021

Inventors: Anirudha V. Sumant, Plainfield, IL, USA; Michael Zach, Stevens Point, WI, USA; and Alan

David Marten, Stevens Point, WI, USA

Assignee: UChicago Argonne, LLC, Chicago, IL, USA

A continuous or semi-continuous process for fabricating nanowires or microwires makes use of the

substantially planar template that may be moved through electrochemical solution to grow

nanowires or microwires on exposed conductive edges on the surface of that template. The planar

template allows fabrication of the template using standard equipment and techniques. Adhesive

transfer may be used to remove the wires from the template and in one embodiment to draw a

continuous wire from the template to be wound around the drum.

Electrical Cable

United States Patent 10,903,159 – Issued January 26, 2021

Inventor: Martin Huber, Obing, Germany

Assignee: MD ELEKTRONIK GmbH, Waldkraiburg, Germany

An electrical cable includes at least two wires extending side by side along a longitudinal cable

direction. The wires are electrically insulated from each other by an insulation. An electrical device is

in electrical contact with the respective wires. A flexible carrier surrounds the wires annularly in

cross section, and the electrical device is mounted on an inner side of the flexible carrier which

faces the wires.

Cable Assembly

United States Patent 10,902,977 – Issued January 26, 2021

Inventors: Thomas Cantz, Stafa, Switzerland; and Reto Casanova, Pfaffi kon, Switzerland

Assignee: HUBER+SUHNER AG, Herisau, Switzerland

The invention is directed to a cable assembly (10, 10a-b), comprising a cable (10, 10a-b) with a cable

hose (11, 11a-b) and at least one conductor (12, 12a-f) arranged therein. The cable hose (11, 11a-b)

is spaced a distance apart from the conductor (12) forming a first interstitial space (15, a-b) between

the at least conductor (12) and the cable hose (11, 11a-b). At least one tube (20, 20a-b) for conveying

of a cooling fluid (21), and a connector (30) comprising at least one contact member (31)

interconnected to the at least one conductor (12) and a chamber (32). Said chamber (32) comprises

a first port (33) which is interconnected to the first interstitial space between the at least one

conductor (12, 12a-f) and the cable hose (11, 11a-b) and a second port (34a, 34a-b) which is

interconnected to the at least one tube (20, 20a-b).

Insulated Electric Wire

United States Patent 10,896,770 – Issued January 19, 2021

Inventor: Masanobu Nakahashi, Tokyo, Japan

Assignee: Hitachi Metals, Ltd., Tokyo, Japan

An insulated electric wire is composed of a conductor, and an insulating layer disposed around an

outer circumference of the conductor. The insulating layer is formed from a fluorine-containing

elastomer composition, and the fluorine containing elastomer composition includes a base polymer

(A) including 70% by mass or more and 98% by mass or less of a copolymer (a1) of

tetrafluoroethylene and an .alpha.-olefin having 2 to 4 carbon atoms, and 2% by mass or more and

30% by mass or less of an ethylene-ethyl acrylate copolymer (a2) (excluding an ethylene-ethyl

acrylate-maleic anhydride ternary copolymer), and a flame retardant (B) including an antimony

compound (b1) and a bromine-based flame retardant (b2), and including 1 part by mass or more

and 9 parts by mass or less of the antimony compound (b1), and 0.3 parts by mass or more and 15

parts by mass or less of the bromine-based flame retardant (b2) per 100 parts by mass of the base

polymer (A).

Metal Wire for Optical Fiber Cable and Strain Relief

United States Patent 10,895,699 – Issued January 19, 2021

Inventor: Mauricio Jochinsen, Fountain Valley, CA, USA

Assignee: Alcon Inc., Fribourg, Switzerland

Various optical fiber cables and systems and methods associated therewith are disclosed herein. An

optical fiber cable may include a jacket, an optical fiber and a metal wire disposed within a passage

defined by the jacket. The metal wire may be coupled to the optical fiber.

Electrical Cable with Improved Installation and Durability Performance

United States Patent 10,889,727 – Issued January 12, 2021

Inventor: Yushin Hawig, Carrollton, GA, USA

Assignee: Southwire Company, LLC, Carrollton, GA, USA

An electrical cable having a conductor having a protecting sheath and/or jacket comprising a base

polymer (such as a thermoplastic or thermoset) having an abrasion reducing agent, a lubricant, a

hydrophobic agent, and/or a UV protecting agent mixed therein. The resulting cable jacket and/or

cable sheath defines an outer surface having abrasion reduction properties, lubricating properties,

hydrophobic properties, and/or UV protecting properties.