Inline Surface Dimensional Flaw Detection and OD/Ovality Measurement Using Laser Line Triangulation on Round Product

There are advantages and disadvantages to every type of inspection method. When it comes to tight-tolerance, highspeed, continuous production of round, opaque and translucent product, laser line triangulation is the superior inspection method. Other inspection methods simply cannot perform at the required level due to the variety of challenges they face when attempting in-process 100% surface inspection. In order to obtain accurate OD and ovality measurements, and in order to detect flaws at any orientation on the product, the inspection method must examine the entire 360° contour of the product. When this is achieved, orientation of the part in the fi eld will have little to no effect on measurement or flaw detection.

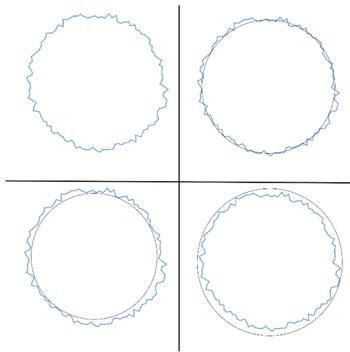

OD and ovality are typical measurements made during continuous production of round product. During startup of a production line, operators attempt to tune equipment parameters to obtain the correct OD and ovality. Once the line is stable and the product is within specifications, the goal is to continuously run until the desired length has been created. Periodic checking of OD and ovality is required to ensure the process is running smoothly. Tighter tolerances necessarily require better measurement accuracy. Also important is the method being used to measure OD and ovality, as different methods present different levels of accuracy and repeatability.