Spotlight on Bows

by Mike McNulty, Editor, Wire & Cable Technology International

Rotating machines such as stranders, bunchers, twinners and cablers use flyer bows to produce helically twisted wires, conductors and cables. All products being processed on these machines come in contact with the bow. More than half of the power required to run the corresponding machine goes toward rotating the bows. In addition, a good amount of the noise generated by a rotating machine comes from the bow, and less aerodynamic bows usually make more noise. Consequently, these bows are pretty important, and they are a main factor in determining the level of success in your rotating equipment operations.

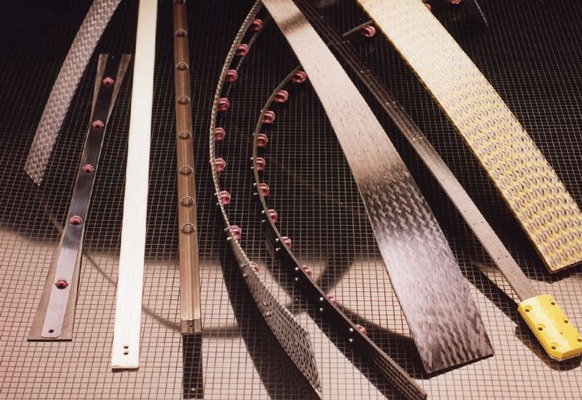

Depending on the style of the machine, one or two curved bows are attached to the rotating element of the machine. The bows get their name from the way they “bow” out in a curved path when installed, which is similar to the shapes of bows designed for hunting. Wire and cable bows, however, rotate at very high speeds, and wires or cables to be twisted travel along the path of the bow before being guided to the pulling capstan and/or take-up reel. The wires or cables are guided along the bow by varying means: eyelets, tubes, strips, rollers, bushings and grooves. With the exception of rollers, all other guiding devices are stationary. For machines that use two bows, the active bow processes the product and the other bow is only used for balance purposes. In a single-bow machine, balance is achieved in other ways.