Evolving Wire Specifications to Improve RF & Microwave Cable Performance

by Jason Rose – Ulbrich Stainless Steels & Special Metals, Inc.

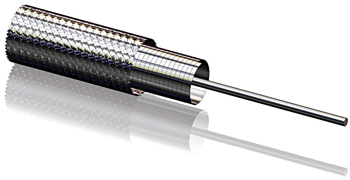

Developing the best possible helical wrap, braid and center conductor products requires understanding the role each plays in the assembled cable. Each component serves a distinct function and has characteristics that are most important to the success of the final cable. Through technical interchange with precision wire suppliers, RF Cable manufacturers can expedite improving wire performance with a two-part solution.

First, reverse engineering—both good and bad samples—is an excellent way to start identifying the characteristics that need to be controlled for the cable’s success. After this, it is instrumental to provide samples that represent necessary changes to improve the overall system’s performance. If the samples are successful, write specifications that capture critical details.