Spotlight on Wipes

Mike McNulty, Editor, Wire & Cable Technology International

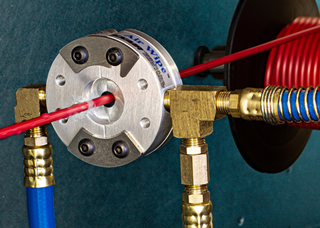

Unwanted liquids can be removed from wire or cable by the use of air or pad wipes. The processes that require wipes include drawing machines, in-line annealers on single and multi-wire drawing machines, extrusion lines (on the exit of the cooling trough), plating, pickling and galvanizing. The liquids that need to be removed from the wire or cable include rinse or cooling water, lubricant, quench, acid, flux and more. Not only is it important to remove the liquid from the wire or cable product, but it is desirable to keep one liquid from contaminating downstream portions of in-line processes. There are two main types of wipes used in the wire and cable industry, pad and air, which are detailed in the following sections.