Featured

Featured Articles

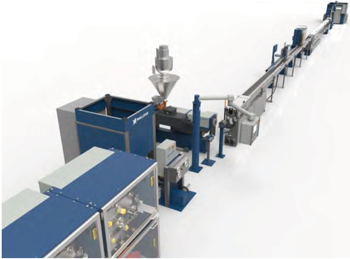

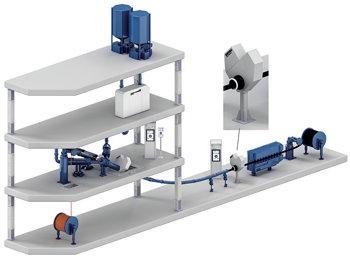

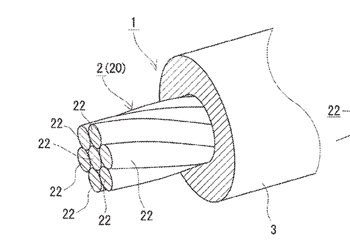

Configuration Optimizer for Fiber Optics Secondary Coating Lines

The global demand for optical fiber cables is increasing at a growing rate. At the same time this market has seen very tight competition between the margins. The key to this problem is in increasing the efficiency of cable manufacturing lines. As an optical fiber cable consists of a bundle of buffer tubes, each potentially covering multiple optical fibers

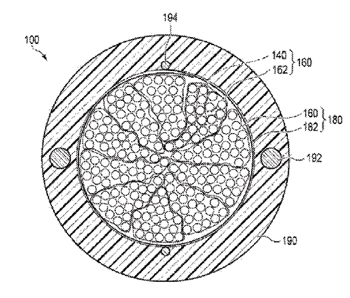

Read MoreUSPTO Wire & Cable Industry Patents for July/August 2022

United States Patent and Trademark Office (USPTO) as compile by the editors of Wire & Cable Technology International Cable Processing

Read MoreFaster Curing Ethylene-Silane Copolymer for Moisture-Cured Insulation & Jackets

Dow’s SI-LINK™ DFDF-5451 NT Faster Curing Ethylene-Silane Copolymer is a new solution for moisture-cured insulation and jackets for use in low-voltage and medium-voltage electrical cables. Specifically, it has a breakthrough contribution of attributes that create value for manufacturers

Read MoreCloser Is Better: Onsite Mexico Manufacturing Training Program

The manufacturing labor force in the USA will have 2.4 million jobs to fill by 2028, according to The Manufacturing Institute. Mexico provides wire harness manufacturers a strong alternative with youthful, cost-competitive labor. Without a commitment to ongoing professional development and continuous improvement, however, Mexico’s workforce will fall behind.

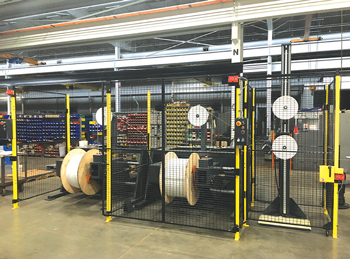

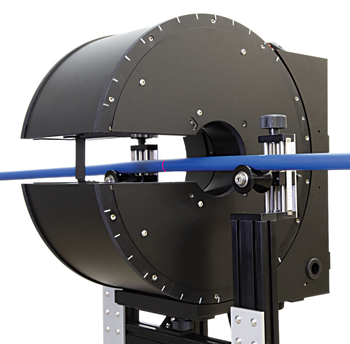

Read MoreCapstans, Dancers, Accumulators Round Up

Suppliers have responded to our call for the state-of-the-art in capstans, dancers and accumulators equipment and technology. Articles are compiled

Read MoreAfter Four Long Years, A Return to Düsseldorf

At last! After being postponed in 2020 because of the COVID-19 pandemic, wire, the International Wire and Cable Trade Fair,

Read More

WAI’s Wire Expo 2022 & Operations Summit

to Set Clear Path for Today’s Wire Makers

by Janice E. Swindells, Wire Association International, Inc. The Wire Association International (WAI), Inc. has announced that the presentations and

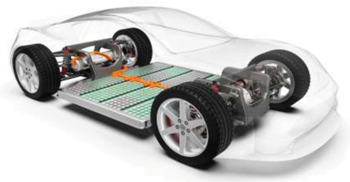

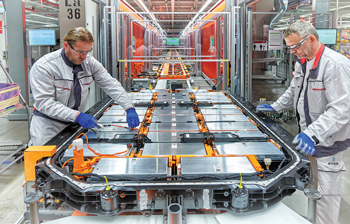

Read MoreSilicones Provide Superior Protection for Cables in Electrical Vehicles (EV)

by Allen Johnson, Elkem Silicones Silicone compounds are being increasingly used by EV manufacturers for their high-performance features in critical

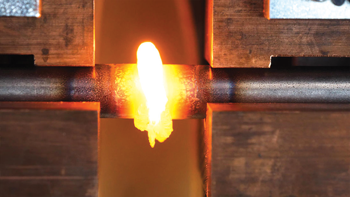

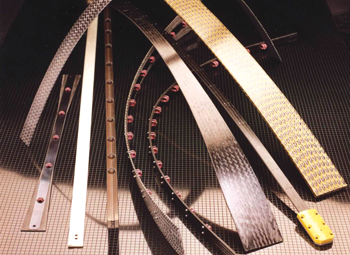

Read MoreOne Versatile Metal Shielding Technology for Many Applications

by Thomas Kulmer, Rosendahl Nextrom GmbH New metal tape forming and welding technology processes copper, aluminum, stainless steel and alloys,

Read MoreCentral Mexico: Affordable, Nearshore Wire Harness Cable Solution

by JP McDaris, Entrada Group The future for the sector lies in Mexico’s interior, where we hire up to 100

Read MoreEfficient Quality Control at the End of the CV Line

Ningbo Orient uses X-RAY 8700 NXT from SIKORA AG, Bremen, Germany, ion order to ensure accurate cold measuring values in

Read MoreWelding Roundup

Suppliers have responded to our call for the state-of-the-art in welding equipment and technology. Articles are compiled by the editors

Read MoreUSPTO Wire & Cable Industry Patents for May/June 2022

United States Patent and Trademark Office (USPTO) as compile by the editors of Wire & Cable Technology International Cable Processing

Read MoreElectric Cars in the Fast Lane

Electric vehicles are gaining strong momentum in the automotive market. High growth rates in new registrations are already driving the

Read MoreBows Roundup

compiled by the editors of Wire & Cable Technology International Suppliers have responded to our call for the state-of-the-art in

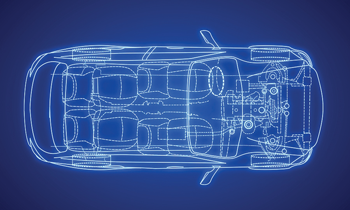

Read MoreSoftware Solutions for Designing Electrical Wire Harness & Cabling Projects

by Glenn Larson, Vias3D Engineers and product designers in transportation, mobility, aerospace, defense and industrial equipment manufacturing face significant challenges

Read MoreHigh-Speed, On-Line Inspection & Measurement

LaserLinc announces the launch of its high-speed, online inspection and measurement system, FlawSense. The system allows manufacturers of high-specifi cation

Read MoreIncreased Access to Industry Solutions, Reimagined Training & Expanded Networking – EWPTE Preview

by Christine A. Siebert – Wiring Harness Manufacturer’s Association The Electrical Wire Processing Technology Expo (EWPTE), the largest industry exclusive

Read MoreTraining the Next Generation of Machinists

John Tomaz – Wardwell Braiding It’s no secret that the manufacturing industry has changed dramatically over the last two decades.

Read More